In easy words, when any organization or group of firms transform raw material, ingredients, components into a customer satisfactory output is called manufacturing goods. The manufacturing industry is extremely powerful and competitive which creates it dominant for such enterprises to have a multicultural solution that can improve efficiency, reduce costs, profitability and boost sales but most importantly, empower the company to make specific, notified and important decisions. An industry resource devising system might be the key to all these demands.

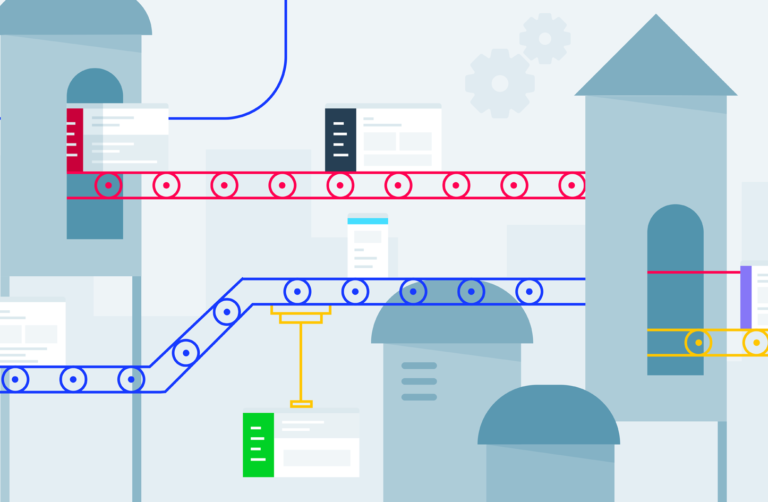

Manufacturing software technology combines all phases of things like resources, services, broadcasting, monitoring, transactions, finance, and accounting and allows companies to run smoothly by controlling a particular database. Employing manufacturing software, it will be simple to handle investment and business.

Some manufacturing softwares used by developed companies:

NetSuite: The method is united with inventory, accounting and commercial management, stockpile management, system management, e-commerce and client relationship management (CRM).

SYSPRO: Enterprise supply outlining software to strengthen the control, combination, and synchronization of the course of the production process for both short-term and long product runs.

IQMS: Advanced particularly for SMB and cumbersome discrete, and shipment process makers in the aerospace, pharmaceutical device, food and drink, automotive, consumer products, packaging, synthetics, and electronics enterprises.

EPICOR: The system is given either on-premise, received, or as a cloud-based Software as an assistance contribution. Fully combined ERP solution with extended functionality used for file control, accounting, pre-production supplies preparation, and production execution.

Special Characteristics offered by this software:

Procurement & Material Management- With this software you can create your acquisition cycle active & sustain excellent merchant relations.

Material Requirement Plan- An essential part of this software works out creation and purchase needs based on bill of elements of completed & semi-finished materials, with due concern to unfinished buying orders, series stocks, and least stocks.

Quality Assurance- Guaranteed quality is the result of powerful discipline over the business process, implemented by the software, performed by quality check on all data, product level trial & process level trial, quality confirmative analysis on dispatches etc.

Production – The end-to-end clarification gives your file control system with the required capabilities to decrease record levels, improve production processes, and enhance visibility beyond your Made-to-Stock sales process.

Production (Project Based)- The manufacturing software when configured for lease /job completion, estimates each job as a design, runs out material call plan for the job, price estimation, trails & controls obtainment based on the job specification, direct job-wise records and reports using variances.

Gate Management- They records all material transfer across the company gate based on due procurement orders or transactions orders, as its powerful control license only authorized supplies/ goods to be produced in & send out of the warehouse premises.

Sales & Dispatch Management- The traffic & dispatch practice automates the whole process from booking to payment, increase productivity, achieve credit system, race up turn around period & fires up the most important MIS required for further transactions strategy & preparation.

Finance & Accounts- Flexible account formation and seamless combination with all company operations grant easy way to the economic effects of regulations. Automated estimating entries reduce errors and conserve time for studying, examining and working on financial information.

Multiple Deployment Architecture- With Tally as a structure, choose on any type of design: hybrid, centralized, or decentralized. The design depends on the figure of areas, connectivity, distance, equipped manpower availability etc.

Security, Controls & Authorizations- Manufacturing software enables to generate user & designate access licenses for various functional areas like shops, accounts etc & of distinct levels which includes merchant, manager etc.

Tally Payroll- It is competent in managing simple Payslip formation in five natural moves to complex associated methods including plying loans and credits, wage revision and arrears totalling, opinions and ad-hoc payments etc.

GST Billing for Manufacturers- Businesses can create GST pliant invoices with the software and also calligraph them. The software takes all necessary details as needed by the GST Act.

GST-compliant has many more benefits. It has built-in functionality to identify, timely and check failures which may take place when entering data. For instance: While arranging bills based on the area of supply, the software will alert you in case you choose inaccurate tax types.

A key features of best manufacturing software:

- Computerized inventory system and more reliable tracking devices in multiple locations. As promptly as there were any transactions or purchases, the mode automatically adapts your stock-list. This is very necessary if you have installed any reordering features and if you have various locations: multistore and warehouse management reduces inventory and potency blind flaws by automating and centralizing catalogue, repository, and satisfaction operations.

- Makes inscribing simple and timely decision making and having the path to specific information at the wrong interval and custom, and being capable to create comprehensive, customized statements will help as a worthy tool for fully-informed choice making.

- Easy passage to knowledge and operational performance where each company must discover a way to unite all of its functions, and for them to be completely integrated, there has to be a stream of reliable, real-time data between them. The report has to be available anytime, anywhere, from any means in all of the fields.

- Improve flexibility and precision and it would assist you to avoid file-level mistake, stock-outs and all the extra loses that normally happen due to human mistake.

- Operational efficiency: It will work as a practical hand to workers, automate jobs and enable you to react no matter where you are, while additionally assuring the safety of the data by assigning the information accessible only to those workers who have been prescribed the rights to see them.

- Easy way to make clients with alliances available with various e-commerce programs and marketplaces. There will a combination with diverse e-commerce floors, so you can hold direct passage to your clients through various marketplaces like Woo Commerce, Shopify and square.

When relating to manufacturing software, it’s necessary to learn the functionality incorporated in each. Reliability is important. If you search escort near me you want to be directed to the proper adult sites like adult search or skipthegames etc. or maybe you are searching for another type of fetish. Either way you want the results you are searching for. Proper applications allow this to be possible.

The most common purposes of these systems are placed below:

Automates the first end of the manufacturing process and duties include preparation and pricing of materials, workers and devices, automatic quoting, request processing and store scheduling. Arrangements should also prepare high-level shipping information from suppliers to overcome getting errors and inscribe any variations in cycle calculations for file management.

MES – Manufacturing Execution System:

Checks the actual production stage and shop level processes and the roles include work-in-progress broadcasting, stock tracking, activity tracking, material utilization and trash reporting.

Manufacturing Accounting:

It will handle all the business transactions and services for a company. In extension to the usual accounting duties, which cover accounts payable, general ledger, inventory and payroll, accounts receivable, the accounting certificate offers help for traffic orders, marketing orders, transfer orders, work-in-progress stories and job fetching modules.

Production Planning & Scheduling:

Plans generation schedules, which are involves hunting lead times, analysing record levels, and creating build-versus-buy choices. This is a subset of preparation, MRP, and scheduling does not usually include automated ordering or file tracking functionality.

PLM – Product Life Cycle Management (PLM):

This software coordinates all production information around the plan, manufacturing, maintaining and distributing of completed goods. It will incorporate computer-aided device software, bill of stock data and record management.

Some benefits of manufacturing software:

- GST Compliant – Manufacturing software is completely GST compliant covering of SGST, HSN Code, IGST, CGST, and UTGST and client and merchant language linked to intrastate and inter-state affairs.

- Dashboard with Graphical Representation – They have the best management’s e-secretary. All you required to understand at one look status of the whole system whether in a factory or on the move.

- Sales Order based Scheduling- Material devising and product planning based on inventory.

- Vendor Rating – Classify vendor into A, B & C and issue warning messages.

- MRP – ORI-wise, ROL-wise, and multiple trade order-wise encourage you to overcome huge record-holding charge as much as 15% with the guidance of DNS built-in algorithm formed after years of practice from the record specialists & experts.

- Barcode for FG items – Protects dispatch administration time and reduces dispatching incorrect element or quantity.

- ASN Facility – Connecting with major ERP software such as Oracle, SAP, etc.

- In-depth Inventory Management System – Provides you 99.9% efficiency of the stock state lying in various locations including welfares at sub entrepreneur as also customer’s stock lying in the same location.

- Stock Availability Alerts – Sends warnings for critical matters when dropping below reorder level to protect last-minute race and hesitated customer delivery.

- Scientific Costing with Graphical Representation – Encourages you to rate highly contentious price at the identical time be beneficial too.

- Comprehensive QC Model – Taking charge of all your ISO records.

- User-friendly and all compliant Payroll module – Wages of 800+ workers or even more can be produced in 5 minutes by simply click of a button!!!

- Auto Email & Auto SMS facility – Forward automated monthly due report to your customers at the beginning of every month.

- Create unlimited Reports as per your format by yourself – This indicates 100% fulfillment to users as statements are according to your defined forms.

- Multiple Alternate Bill of Material for the same item- Conserving huge time in managing multiple FG forms codes for scanty variants of substance.

- Comprehensive Accounts Module – GL Linkages provides no